The pad is one of the most important elements in the pad printing process. The correct choice is essential in obtaining good final print results. The pad is made with a special silicone rubber with the following characteristics.

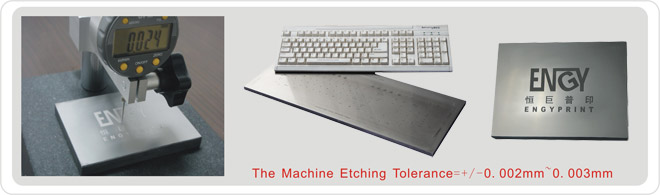

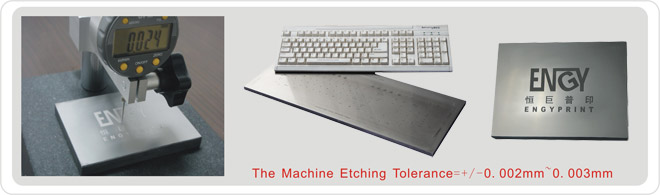

>> The spray nozzles and the plate holder staggered are swing during etching work, ensure the higher etching precision.

|

Main Voltage |

380V/50Hz |

|

Power Rating |

3.1KW |

|

Machine Size |

l1145mmxW435mmxH800mm |

|

Liquid Tank Capacity |

150L |

|

Max.Etching Size |

300mmx600mm |

The EN-SK6000 etching machine especially be recommended to use in the pad printing plate making etching work. It is easy to operate and the etch depth can be control by the machine work time controler system, instead of the worker's experience, it will make the etching quality keep stable and better.

The EN-SK6000 etching machine especially be recommended to use in the pad printing plate making etching work. It is easy to operate and the etch depth can be control by the machine work time controler system, instead of the worker's experience, it will make the etching quality keep stable and better.>> The spray nozzles and the plate holder staggered are swing during etching work, ensure the higher etching precision.

|

Main Voltage |

380V/50Hz |

|

Power Rating |

3.1KW |

|

Machine Size |

l1145mmxW435mmxH800mm |

|

Liquid Tank Capacity |

150L |

|

Max.Etching Size |

300mmx600mm |

Due to the tray-type design, the EN-SK/6200 etching machine is specially to etching the single-sided small metal parts, such as the metal brandss, watch shell, mobile phones accessories, glasses frames, the electron products metal keyboards, metal decorative pleces and many kinds of metal fittings,etc.

Due to the tray-type design, the EN-SK/6200 etching machine is specially to etching the single-sided small metal parts, such as the metal brandss, watch shell, mobile phones accessories, glasses frames, the electron products metal keyboards, metal decorative pleces and many kinds of metal fittings,etc.>> Esay operate and low investment for this machine.

|

Main Voltage |

110V; 220V; 380V/50~60Hz |

|

Power Rating |

4.5KW |

|

Machine Size |

L1300mmxW770mmxH1390mm |

|

Max. Etching Size |

300mmx600mm |

|

Liquid Tank Capacity |

150L |

|

Customiz |

Special size can be customiz to customers request. |

The EN-SK/C600X etching machine is especially recommended for the metal sign cards or metal parts which need to etch double sides or need etch hollows with great precision and high output.

The EN-SK/C600X etching machine is especially recommended for the metal sign cards or metal parts which need to etch double sides or need etch hollows with great precision and high output.>> Metal parts conveyer automaticly, easily operate with high putout efficiency.

|

Main Voltage |

380V/50Hz |

|

Power Rating |

7kw |

|

Max.Etcing Width |

600mm |

|

Etching Area Length |

900mm |

|

Machine Size |

L2300mmxW1500mmxH1460mm |

|

Liquid Tank Capacity |

250L |

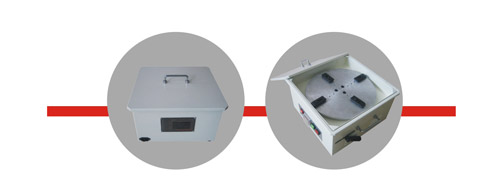

This coating unit is based on the certrifugal principle to make the photosensitive emulsion uniformly lay on the thick steel plate.The rotation speed set can be adjusted, the operator can easily cotrol the coating layer thicker or thinner according their exposure needing.

This coating unit is based on the certrifugal principle to make the photosensitive emulsion uniformly lay on the thick steel plate.The rotation speed set can be adjusted, the operator can easily cotrol the coating layer thicker or thinner according their exposure needing.

|

Main Voltage |

220V/50Hz |

|

Power Rating |

45W |

|

Machine Size |

L400mmxW400mmxH255mm |

|

Turntable Size |

Dia.320mm |

|

Max.Coating Size |

200mmx200mm |

The model of SJ200A increase the protective cover and wheel brakes, make the coating operations more environmentally friendly science.

The model of SJ200A increase the protective cover and wheel brakes, make the coating operations more environmentally friendly science.

|

Main Voltage |

220V/50Hz |

|

Power Rating |

45W |

|

Machine Size |

L400mmxW400mmxH230mm |

|

Turntable Size |

Dia.320mm |

|

Max.Coating Size |

200mmx200mm |

This exposure unit is applicable to the cliche plates exposure, including the thick and thin steel plate for pad printing. The MINI table style design with lower power-rating UV light source, greatly improving the exporsure efficiency and signficant saving in electricity costs. This unit is very easy to operate, the work time control system ensure the presise exposure result.While,it is convenient to carry and move with its mini body for the customers if they need carry it around often.

This exposure unit is applicable to the cliche plates exposure, including the thick and thin steel plate for pad printing. The MINI table style design with lower power-rating UV light source, greatly improving the exporsure efficiency and signficant saving in electricity costs. This unit is very easy to operate, the work time control system ensure the presise exposure result.While,it is convenient to carry and move with its mini body for the customers if they need carry it around often.

|

Main Voltage |

220V/50Hz |

|

Power Rating |

60W |

|

Machine Size |

L600mmxW250mmxH170mm |

|

UV Lamp |

PHILIP UV Lamp 15wX4 |

|

Max.Work Spec |

150mmx350mm |

|

Exposing Time |

60-90s |

The EN-BG/2000 exposure unit adopt the UV light up from the bottom, the automatic vacuum system and the exposure time controller ensure the presise exposre result. This unit applies to exposing both the pad printing cliches and the screen printing plates.

The EN-BG/2000 exposure unit adopt the UV light up from the bottom, the automatic vacuum system and the exposure time controller ensure the presise exposre result. This unit applies to exposing both the pad printing cliches and the screen printing plates.

|

Main Voltage |

220V/50Hz |

|

Power Rating |

2.25kw (Light:2kw) |

|

3.25kw (Light:3kw) |

|

|

4.25kw (Light:4kw) |

|

|

Machine Size |

L1260mmxW970mmxH940mm |

|

Max.Exposure Size |

900mmx1200mm |

|

Lamp |

UV Lamp |

|

Customiz |

Special size or power rating can be customizd to your requesting. |

|

Main Voltage |

220V/50Hz |

|

Power Rating |

1.2kw (Light:1kw) |

|

2.5kw (Light:2kw) |

|

|

3.5kw (Light:3kw) |

|

|

4.5kw (Light:4kw) |

|

|

Machine Size |

L850mmxW750mmxH1650mm |

|

Max. Exposure Size |

600mmx700mm |

|

Cutomize |

Special Voltage or exposure size can be cutomize to your needing. |

The EN-BG/3000 exposure unit adopt the design of top UV light source, it is suitable for the thin or midium thickness cliche plates exposure by single-side. The machine's automatic vacuum system and the exposure time controller ensure the presise exposre result.

The EN-BG/3000 exposure unit adopt the design of top UV light source, it is suitable for the thin or midium thickness cliche plates exposure by single-side. The machine's automatic vacuum system and the exposure time controller ensure the presise exposre result.

|

Main Voltage |

220V/50Hz |

|

Power Rating |

1.2kw (Light:1kw) |

|

2.5kw (Light:2kw) |

|

|

3.5kw (Light:3kw) |

|

|

4.5kw (Light:4kw) |

|

|

Machine Size |

L850mmxW750mmxH1650mm |

|

Max. Exposure Size |

600mmx700mm |

|

Cutomize |

Special Voltage or exposure size can be cutomize to your needing. |

FUJI FMR-40 series for pad printing

.....FUJI FMR-40 Photosensitive Emulsion Coating

.....FUJI FMR Developer

.....FUJI FMR Blue Dyed Developer

Specifications:

1. Excellent coating & exposure result

|

Place of Origin:Japan |

Brand Name:FUJI |

Model :FMR-40 |

|

Color:Crystal |

Shelf Life:2years |

Packing:2L/can |

|

Use:Coating in pad printing plate making process. |

||

Corrosion Resistance Photosensitive Ink (Blue Emulsion)

Package standard.................5L/can

Developing Powder

Package standard.................500g/bottle

Coating Cleaning Powder

Package standard................. 1000g/bottle

![]()

Acid Etching Liquid (apply handwork etching)

Steel Etching Liquid.......... 1L/bottle

Chrome Steel Etching Liquid......0.5L/bottle

Etching Chemical Powder

Package standard.................40kg/box

|

Cup Body Material

|

D (mm) Outer dia. |

d (mm) Inner dia. |

H (mm) Ring hight |

Magnet |

|

PL (Plastic cup)

|

65 |

60 |

5.2 |

0 |

|

96 |

90 |

5.2 |

0 |

|

|

125 |

120 |

5.2 |

0 |

|

|

135 |

130 |

5.2 |

0 |

|

Cup Body Material

|

M (qty) Magnets |

D (mm) Outer dia. |

d (mm) Inner dia. |

H (mm) Ring hight |

Ring Edge |

|

AL (Aluminium cup)

|

6M |

90 |

82 |

12 |

SD |

|

8M |

90 |

82 |

12 |

DD |

|

|

10M |

100 |

90 |

12 |

SS |

|

|

10M |

100 |

90 |

12 |

DS |

|

|

14M |

120 |

110 |

12 |

SD |

|

|

16M |

130 |

120 |

12 |

SD |

We customize the varieties of ink cups to your printers with your sample or drawing.

Pad Printing Ceramic Rings and Carbide Rings for Inkcup

Pad Printing Ceramic Rings and Carbide Rings for Inkcup

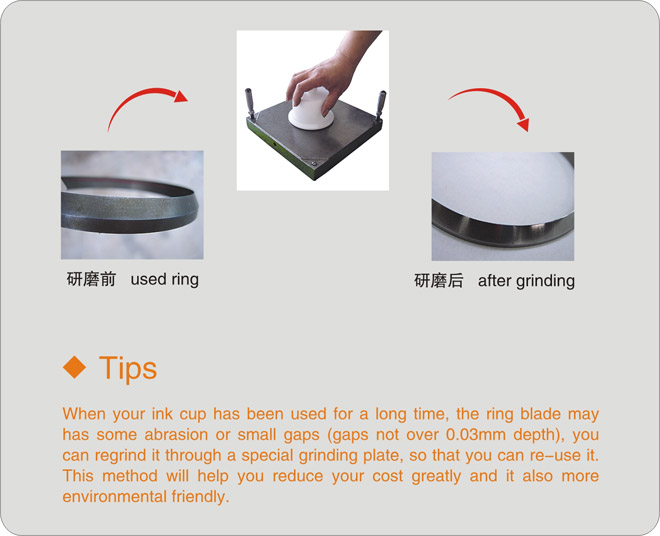

There has been much debate as to which doctor ring material is best for doctoring printing plates. The market for pad printing supplies originally started with carbide steel doctor rings and many were successfully implemented, however, since the ceramic ring was brought to the market it has been extremely successful as well. We would guess that now the pad printing marketplace is evenly divided between the carbide ring and the new generation ceramic doctor ring. Today, both carbide rings and ceramic rings work extremely well. It is our opinion however, that the ceramic doctor ring offers some advantages.

1. One of the primary advantages of the ceramic ring has a "self-lubricating" qualities that make I work equally well on thin steel and thick steel and the softer polymer printing plates. The carbide doctor rings are generally fairly sharp and abrasive and will wear a polymer plate material quickly.

2. Another advantage of the ceramic ring is that it is generally thicker, more robust and resistant to damage by during handling. Most ceramic rings taper from the inside and outside diameter to a "point" roughly. 006" leaving plenty of material near the tip. Carbide rings, however, taper from the outside diameter only to a "point" with a cross section of. 003" leaving only a minimum amount of material near the tip resulting in more damage during operator handling. The combination of the ring profile and the brittle nature of carbide make damage to rings fairly frequent during ordinary use.

In general, the quality of pad printing supplies has become very high, so any type of sealed inkcup or ring material allows making excellent imprints.

|

Ring Material |

D (mm) Outer dia. |

d (mm) Inner dia. |

h (mm) Height |

|

Carbide Ring (Tungsten steel Ring) |

65 |

60 |

5.2 |

|

70 |

60 |

12 |

|

|

90 |

82 |

12 |

|

|

96 |

90 |

5.2 |

|

|

100 |

90 |

12 |

|

|

120 |

110 |

12 |

|

|

125 |

120 |

5.2 |

|

|

145 |

140 |

6 |

|

|

200 |

190 |

12 |

Blades are often considered to be the least important element in the pad printing process, with the open system. In fact, their characteristics determine print optimization and more importantly, the life of the etched plate. It is for these reasons essential that blades are manufactured from special high quality steel with perfectly uniform thickness, and that the chamfer is made with absolute accuracy.

Blades are often considered to be the least important element in the pad printing process, with the open system. In fact, their characteristics determine print optimization and more importantly, the life of the etched plate. It is for these reasons essential that blades are manufactured from special high quality steel with perfectly uniform thickness, and that the chamfer is made with absolute accuracy.